The basic principles of plastic recycling

Recycling means creating closed loops of raw materials. The ambition is to reprocess plastic scraps without a loss of quality, to a recycled raw material for the production of final products. Morssinkhof – Rymoplast operates in both the mechanical and chemical recycling market, to achieve the goal of sustainable usage of raw materials.

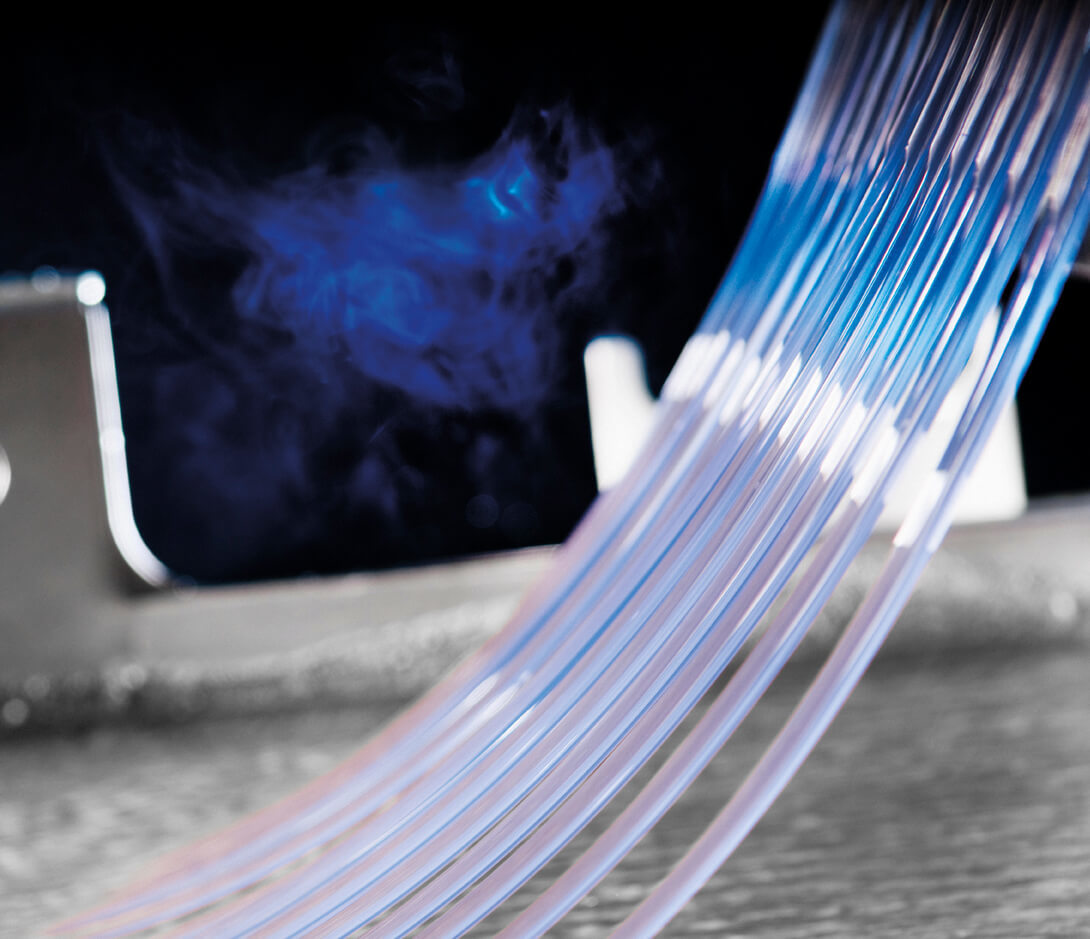

Mechanical Recycling

Mechanical Recycling can be defined as the treatment of plastic scraps through sorting, grinding, purification and revaluation without the need for a significant change of the chemical structure of the material. By means of this technique a sustainable raw material can be produced, which results in a new life cycle and a new usage purpose.

Mechanical Recycling a highly applicable method for plastic monostreams: a monostream usually consists of one type of polymer which is often collected separately. In case multiple types of polymer are used within a product or packaging, it is required that they can be separated by using mechanical techniques.

Chemical Recycling

Some plastic scrapes consisting of multiples types of polymer cannot be separated through mechanical techniques, for example multiple layer packaging and other complex plastics. Chemical recycling will then be used to regain the raw materials.

Over the past few years, chemical recycling has made a rapid development. Chemical processes are being used in this method to break down the plastic, to purify it, and to create new polymer.

In cooperation with our partners DSM-Niaga and Cumapol, Morssinkhof – Rymoplast is working on an enhanced recycling techniques under the name of CuRe Technology. In case you would like to know more about CuRe Technology, please press the button below.